By Anna Berry, B.C.E.

Unlike many of the pests we protect food from, stored product pests (SPP) live in the food they are consuming. They do not travel from a safe harborage to a food source and then return back to their harborage — the harborage is the food source. The living preferences of species of SPP will vary based on its food preference — some will thrive in whole kernels of corn, others will prefer processed grains and others may choose a food source high in protein.

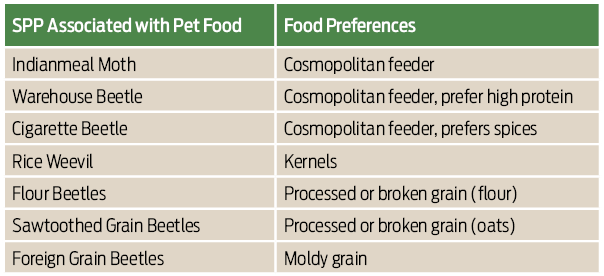

When we look at the food chain of custody, how food travels from harvest to end-user, we can pinpoint which facilities will be more prone to certain types of stored product pests based on the food they store or process. Grain silos may wrestle with weevils, which prefer a kernel; a commercial bakery may wrestle with flour beetles, which prefer processed grain; and a spice factory is at risk for cigarette beetles, which are excellent at making unappetizing food edible. Stores that sell dry pet food will find they’re at risk for all species of SPP, making them a challenging facility for pest management.

THE SOURCE. Infestations in a pet food store (or retail store selling dry pet food) most commonly originate from the following sources:

1. Food Itself: Despite best efforts, sometimes infestations will start at the pet food manufacturing plant. After processing but before packaging, stored product pests will take advantage of exposed food and begin infesting. The size of the infestation is dictated by how many individuals made it into the container, the temperature the product is stored at and how long the product remains in storage. As long as the infestation is contained in the bag, these are the easiest types of infestations to solve: simply identify and discard the product and its inhabitants.

2. Environment: The “wandering” larval stage of several species of SPP, particularly the warehouse beetle and the Indianmeal moth, are adept at leaving their food supply to find a calm, quiet place to pupate and become adults. Once they leave the food, they’ll look for a suitable habitat on the shelves or racking on which the food was stored. The infestation then becomes a “structural infestation” — removing the original source will not solve the problem. The resulting adults typically will find spilled food to make their home in and some species will bore into product and infest previously uninfested food. The same thing can happen during transport. A truck that carried infested product may become infested, putting subsequent foods at risk.

3. Exterior: Some species of SPP are prevalent outside. A pet food store is attractive to these pests and if it has unsealed openings/food spillage, it may become infested.

MINIMIZE RISK. Steps that will decrease the likelihood of developing an infestation:

• Sanitation: Since SPP live in food, the most effective way to remove/limit them is to remove food sources. In a pet store, this is best achieved via thorough cleaning of shelves/racks. While the entire pet food store may be at risk, the source isn’t the entire pet food store. It’s the small forgotten places where food debris has gathered. Hard-to-access areas have food debris build up, an excellent hidden habitat for SPP.

• Minimize Voids Where Food Collects: Shelves and racking should be installed to have as few food-collecting pockets as possible. The u-channels common in racking design are notorious for collecting and hiding debris that warehouse beetles infest. Voids in peg boards and under shelving collect fallen food, attracting several species.

• Follow First-In, First-Out: Proper stock rotation is one of the best ways to minimize risk. SPP need food, but they also need time. It takes about 30 days to go from egg to adult for most species in an ideal environment. The sooner the product is off the shelves, the less time there is for an infestation to grow. Forgotten product that sits undisturbed for months is left to provide harborage to generations of SPP. Depending on the species, we may not even know they’re in the product because they have no need to leave. These items bring so much risk to the facility because when they do need to leave the product to find food, they’ll begin infesting the structure and even more products.

• Inspect Incoming Product: Often there’ll be clues that a product is coming into the store infested. Employees trained to identify these clues can flag or decline product before it hits the shelves. Evidence may include seeing adult or larval stages of the insects, webbing (in the case of stored product moths), shed larval skins, pupal casings in the seams of bags, or small holes where larvae have bored in or out or adults of some species have chewed through.

• Preventively Freeze Product: Stored product pests are temperature sensitive and are most prolific in warm climates. Very high temperatures and very low temperatures slow the insects down and eventually kill them. Freezing can be an excellent way of killing insects in potentially infested food before putting them on the shelves. If a store has the means, identifying consistently infested brands or types of food and implementing a freezing protocol before putting them on the shelves can significantly reduce risk.

• Preventive Chemical Application: Residual chemicals, which kill the insects upon contact, can have a place in stored product pest management, but choosing where to apply needs to be carefully considered. Since the insects live in food, and we cannot apply residual chemical to food or packaging, we’re limited to cracks and crevices that the insects may or may not encounter. Insect growth regulators can be an effective tool against Indianmeal moths and warehouse beetle larvae, which wander away from food to pupate.

• Seal Entry Points: Indianmeal moths, warehouse beetles and flour beetles (as well as secondary feeders such as foreign grain beetles) can have outdoor populations. Ensuring doors are kept closed and sealed will help in keeping pests outside.

CONTROLLING POPULATIONS. Due to the sensitive nature of a pet food store (particularly one that also sells pets or allows pets to roam the aisles), controlling infestations beyond the preventive measures previously listed can be challenging. Sanitation will consistently play a part in control: as long as there is food available for a SPP pest population, there is a place for populations to retreat to. Cleaning one area where we’re seeing activity doesn’t necessarily eliminate the population; the population may move to another area. Diligent sanitation efforts are necessary. Outside of sanitation, control may be partially achieved through ultra-low volume treatment, which will kill exposed adult stages of the pests. This will not affect the juvenile stages in the food itself, though, making it a temporary solution.

Fumigation can achieve control, though this is typically costly for retail stores. One tool that is being used more frequently against Indianmeal moth populations is mating disruption. This solution saturates the air with synthetic Indianmeal moth sex pheromone, camouflaging the actual female’s sex pheromone. The male is unable to find her and the two eventually die of natural causes without reproducing. When Indianmeal moth is the target pest, this method has proven to be effective.

Pet food retail environments are vulnerable to SPP and that puts brand reputation on the line. A proactive pest management program with a strong emphasis on sanitation is the most effective way of protecting food.

Anna Berry, BCE, is the training manager/entomologist for McCloud Services. She is a member of the Copesan Technical Committee (CTC).

This Tech Talk article was originally published in the November 2019 edition of PCT magazine.